NFCs are becoming increasingly important due to their ecological advantages, especially in sustainable material development. However, recycling these materials poses a major challenge, as the methods available to date are either inefficient or environmentally harmful. In the technical field, the project focuses on the development of biomimetic, optimised joining and unjoining concepts to enable multiple uses of NFK, testing pyrolysis processes, using recyclable resin systems, and utilising energy for green steel. These measures are intended to optimise the recycling process and increase the material recyclability of NFK. Economically, the project aims to develop sustainable, cost-effective solutions that enable profitable recycling of NFK. Scientifically, the project aims to deepen understanding of material properties and their processing capabilities, thereby promoting future developments in this area. Another focus is on “design for recycling” to optimise the recyclability of components from the earliest design phase. Establishing a material and component database and integrating RFID chips are intended to ensure long-term traceability of material composition. The aim is to create closed component and material cycles and to sustainably increase resource efficiency.

Partner:

Funding: European Union and Free Hanseatic City of Bremen (EU/FHB) / BAB – Bremer Aufbau-Bank

Project duration: 12/2025 - 11/2027

Project leader: Prof. Dr.-Ing. Jörg Müssig

Project co-worker: Jonas-Rumi Baumann

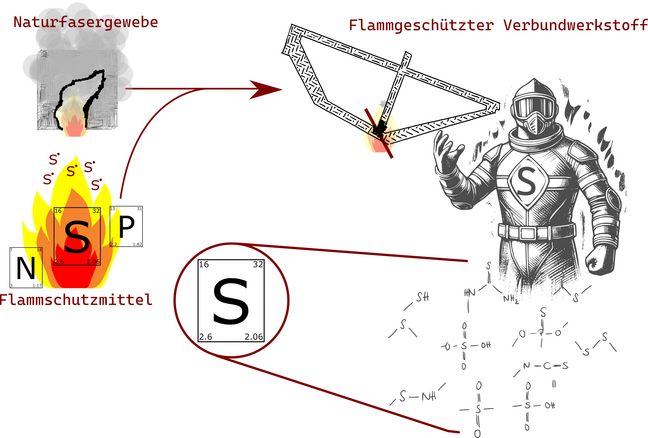

The Europe-wide ban on halogenated flame retardants (FSM), combined with increased flame-retardancy requirements for textiles, plastics, and fibre composites, has led to considerable interest in effective, halogen-free alternatives. The problems with current and new halogen-free FRMs are their low flame retardancy, the quantity required to achieve adequate protection, which affects mechanical properties, and poor wash resistance. The use of sulfur-containing compounds in polymers shows promising results in terms of flame retardancy, which can be improved by the synergistic effect of nitrogen and phosphorus. The project focuses on developing sulfur-containing FSMs for bio-based fibre composites. The development goal is to create efficient systems with performance comparable to halogenated FSMs, which are characterised by good flame retardancy, low mass requirements, and high permanence. Among other things, the project addresses the toxicological and environmental hazards of common halogenated flame retardants and identifies more efficient alternatives. Ideally, the materials' mechanical properties will be improved.

Partner: Deutsches Textilforschungszentrum Nord-West (DTNW)

Funding: Bund, Bundesministerium für Wirtschaft und Klimaschutz (BMWK)

Project duration: 11/2024 – 10/2026

Project leader: Prof. Dr.-Ing. Jörg Müssig

Project co-worker: Alexander Behrens

Cellulose fibre bundles, which form the vascular bundles of bamboo and run from node to node, can be obtained by dissolving the lignin, hemicellulose, and pectins. The sustainability of bamboo as a raw material stems from its high growth rate and its ability to be cultivated on less demanding soils. This sustainability potential is significantly reduced by the possibility of transport to Europe. An alternative approach to obtaining cellulose fibres involves using native reed. Cultivating reed on currently drained moorland areas can create an incentive for rewetting, in line with the national moorland conservation strategy. Due to its morphological similarity, reed is a suitable European alternative to bamboo. The project aims to create further utilisation prospects for the cultivation of paludipflanzen (marsh plants). The project involves the extraction of cellulose fibre bundles from bamboo and reed. The cellulose fibre bundles will form the basis for the production of semi-finished products in the form of UD tapes, from which composite materials are then manufactured.

Funding: Bund, Bundesministerium für Forschung, Technologie und Raumfahrt (BMFTR); Ideas for Bioeconomy

Project duration: 10/2025 - 09/2026

Project leader: Prof. Dr.-Ing. Jörg Müssig

Project co-worker: Alexander Behrens

In the EMPHATI project, Dutch and German companies and scientific institutions are working together to develop new, sustainable, and environmentally friendly products based on PHA (polyhydroxyalkanoates). PHAs are naturally occurring biodegradable polymers. The aim of this cross-border project is to develop new, sustainable, environmentally friendly products based on PHA/PHA blends with natural fibres for selected applications in injection moulding and 3D printing within the participating manufacturing companies. A supporting LCA analysis will also be carried out across the entire circular economy, from PHA production to end-use scenarios. The focus is on expanding and furthering cooperation between Dutch and German companies and knowledge institutes. A key aspect is the formation of a cross-border cluster along the PHA value chain, which connects all stakeholders and enables knowledge transfer. Feasibility and pilot studies are to be carried out in an open part of the project.

Partner: see project homepage

Funding: Interreg VI A Deutschland-Nederland 2021-2027

Project duration: 10/2022 - 06/2026

Project leader: Prof. Dr.-Ing. Jörg Müssig

Senior researcher: Dr.-Ing. Nina Graupner

Project co-worker:

The MUSHCORE project aims to investigate the suitability of edible mushroom mycelium for use as a core material for technical sandwich composites. Therefore, the investigation of innovative utilisation options is an important and rapidly developing field of research. The use of paludiculture biomass as a growing substrate for edible mushrooms, combined with the targeted interweaving of the substrate with mycelium into sandwich cores, can form such a regional value chain. In collaboration with Pilzschmiede in Bremen, various edible mushroom strains will be tested for yield on different substrates made from paludiculture biomass. The interwoven substrates will be mechanically characterised in various tests to determine their suitability as sandwich core materials. The best variants will be used to produce and test sandwich panels with different cover layers made of natural fibre-reinforced plastics. The bio-based sandwich panels produced in this way could be used for mushroom cultivation and transport boxes, furniture, or floor panels for food trucks.

Partner:Pilzschmiede

Funding: Hochschule Bremen - R&D Fund

Project duration: 04/2025 - 03/2026

Project leader:Prof. Dr.-Ing. Jörg Müssig

Project co-worker:Jonas-Rumi Baumann

The aim of the project ‘Sustainability of paludicultures with special consideration of the nutrient balance (NAPALU)’ is to quantify the influence of nutrient supply and other relevant factors (e.g. water levels) on the medium and long-term yield and quality development of fen paludicultures as well as on environmental impacts and utilisation options in Bavaria and Lower Saxony. The project aims to assess the medium-term sustainability of fen paludicultures with respect to productivity, utilisation pathways and economics, on the one hand, and water and nutrient dynamics, biodiversity, and climate relevance, on the other. In addition, selected utilisation and product lines are to be developed and prototypically implemented. To this end, the market opportunities of promising, previously less intensively investigated products and applications that offer the highest possible added value will be analysed. The project offers a unique opportunity to comprehensively evaluate the ecological and economic sustainability of various paludicultures for the first time by integrating already established fen paludiculture areas.

Partner: see project homepage

Funding: Bund, Bundesministerium für Ernährung und Landwirtschaft (BMEL)

Project duration: 11/2022 - 01/2026

Project leader:Prof. Dr.-Ing. Jörg Müssig

Project co-worker:Jonas-Rumi Baumann

The NF market study aims to comprehensively examine the current market situation of the natural fibre industry in Germany and Europe. In view of increasing sustainability requirements and uncertainties in global raw-material supply, regionally grown natural fibres such as hemp and flax are becoming increasingly important. These sustainable fibres offer valuable alternatives to synthetic materials across industries, including textiles, construction, and fibre composites, and open new perspectives for future-oriented applications such as electromobility and sustainable architecture. A key focus of the study is on the availability of natural fibres and the investigation of regional cultivation potential and economic benefits for German agriculture. The aim of the study is to identify opportunities and risks for the natural fibre industry and to formulate recommendations for action for companies and political decision-makers. This analysis updates the results of the 2013 market study and provides a strategic framework for action across the entire value chain of the natural fibre industry.

Partner:

Funding: Bund, Bundesministerium für Ernährung und Landwirtschaft (BMEL)

Project duration: 08/2024 - 11/2025

Project leader:Prof. Dr.-Ing. Jörg Müssig

Project co-worker:Jonas-Rumi Baumann

Our research initiative aims to improve the long-term durability of natural fibre composites. This project focuses on optimising fibre/matrix adhesion and reducing moisture absorption in sandwich composites. Great importance is attached to the ease with which our findings can be implemented in business practice. The research aims not only to improve the quality of products and components made from natural fibre composites, but also to promote their sustainability. This project represents an important bridge between scientific knowledge and practical application, enabling companies to develop competitive, durable, and environmentally friendly products. The results of the research will not only help transform the composite materials industry into a more sustainable one but also extend the service life of natural fibre composites. The target products are marine applications made with sandwich panels and mobile architecture applications, such as tiny or modular houses. Furthermore, the optimised natural fibre composites could be suitable for use in modules for roof extensions during the renovation of old buildings.

Partner: Greenboats GmbH

Funding: European Union and Free Hanseatic City of Bremen (EU/FHB) / BAB – Bremer Aufbau-Bank

Project duration: 01/2024 - 10/2025

Project leader:Prof. Dr.-Ing. Jörg Müssig

Project co-worker:Raja Bade

The main objective of the project is to develop and optimise flat, mineral-bonded panel materials with modified natural fibre reinforcements for outdoor use, such as building envelopes. The focus is on increased toughness, reduced production costs, and improved dimensional stability. To achieve these goals, wood-based natural fibres (cellulose) and other lignocellulose fibres are pretreated and then functionalized using various routes, making them suitable for use in cement-bound materials. The use of bio-based fibres instead of synthetic fibres as reinforcement in cement is intended to improve mechanical properties. Furthermore, this combination of materials can increase and extend the durability and thus the service life of the components, while reducing costs and improving the ecological balance. The overarching project goal is to increase the added value of previously largely unused plant-based “by-products,” including those from pulp production, for use as reinforcement in mineral-bound building materials. Another key project goal is to improve the CO2 balance.

Partner:

Funding: Bund, Bundesministerium für Bildung und Forschung (BMBF) / EUREKA

Project duration: 03/2023 - 02/2025

Project leader:Prof. Dr.-Ing. Jörg Müssig

Project co-worker:Alexander Behrens

Microbond sample with viscose regenerated cellulose fibre of fineness 3,3 dtex (Danufil®- Kelheim Fibres GmbH, Kelheim, DE) with a droplet of polyethene (NR 000491 Lupolen, LyondellBasell Industries, Rotterdam, NL)

Natural/Regenerated cellulose fibre-reinforced composites often exhibit poor fibre/matrix adhesion due to the incompatibility between the hydrophilic reinforcing fibres and hydrophobic matrix. In the current project, industrially developed continuous regenerated cellulose fibres and polyethene (potentially of bio-based origin) are used to manufacture fibre-reinforced composites by introducing an intermediate step of UV irradiation of a semi-finished composite sample (Figure 1). This approach assumes that a cross-linked transition layer can be formed at the interface between UV transparent matrix and UV adsorbing fibres, thus avoiding petrochemical adhesion promotors. The effect of UV irradiation on the fibre/matrix adhesion is characterised by analysing the performance of the UV irradiated fibre-reinforced composite through single fibre tensile, micro-bond, tensile, double notch, and fatigue tests.

Funding: The research Project IGF-No. 21818 N of Forschungskuratorium Textil e. V. was funded by the Bundesministerium für Wirtschaft und Energie in the framework of the program Industrielle Gemeinschaftsforschung (IGF) based on a decision by Deutscher Bundestag.

Project partners:

Project duration: 01.05.2021 – 30.04.2023

Project leader: Prof. Dr.-Ing. Jörg Müssig

Project co-worker: Raja Bade

Lightweight design, especially with natural fibre-reinforced composites, is essential to match sustainability demands within the mobility sector. Lightweight construction methods such as the established sandwich structure in combination with bio-based natural fibre-reinforced composite materials are of great relevance, which should represent an alternative to established metallic structures or glass fibre-reinforced petrochemical composite structures. In the GreenBox project, natural fibre-reinforced sandwich structures are being developed and manufacturing processes optimised for scalable industrial series production. This is being pursued to reduce the environmental impact on several levels and take a step towards sustainable mobility.

Funding: This project (VE4127B) was funded by the European Regional Development Fund (ERDF)

Project duration: 10/2021 - 09/2023

Project leader: Prof. Dr.-Ing. Jörg Müssig

Project co-worker: Raja Bade & Jan-Marten Sprenger

Press release: JEC Composites Innovation Awards - Nomination

The polymer processing industry is aware of the need for sustainable plastic solutions. Polymer waste streams are available but do not find appropriate applications.

Mid-range mechanical performances can be obtained by combining available recycled commodity thermoplastics (PE/PP and its variants) or biobased thermoplastics (PLA) with natural fibre reinforcement (e.g., flax) and appropriate additives. Using recycled materials in combination with natural fibres (virgin and recycled flax) results in a fully sustainable solution. Recycled polymers are also cheaper than new materials in most cases, which further illustrates the economic potential of this research approach. Literature review and previous research showed that it is possible to use straw flax instead of the heavily processed, and therefore more expensive, flax fibres typically used in the textile industry. In Western Europe, textile flax can only be cultivated in limited regions, whereas oil flax can be grown in a much larger area. Up to now, the stems of oil flax accumulate as a non-used waste product during the flax seed harvest.

This project aims to develop and apply an industrially relevant, fully sustainable compound with oil flax stems as a reinforcement. The new compound should possess satisfying mechanical properties and be economical simultaneously.

The IGF research project No.: 308 EN (as part of a transnational CORNET project) was funded by the Bundesministerium für Wirtschaft und Klimaschutz (BMWK) in the framework of the program Industrielle Gemeinschaftsforschung (IGF) based on a decision by Deutscher Bundestag.

The project aims to recover nettle as a fibre crop by using its ability to grow on marginal land that would otherwise remain under-used. To achieve this goal, the European partners examine the following aspects: Nettle biomass production on marginal lands and processing its fibre yield into bio-based materials. Investigation of possible processing constraints, such as uptake of contaminants into usable biomass, due to the soil conditions. Effect of poplar co-cropping on soil and nettle fibre conditions. The gathered information will be set in a broader commercial feasibility and sustainability context.

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 771134. The project NETFIB was carried out under the ERA- NET Cofund SusCrop (Grant N°771134), being part of the Joint Programming Initiative on Agriculture, Food Security and Climate Change (FACCE-JPI).

The flammability of natural and cellulose fibre-reinforced plastics is a major problem concerning their use for demanding applications, e.g. in the transport sector. In the flame retardancy project, textile semi-finished products are equipped with boron-containing flame retardants so that they are less easily flammable and have a smoke suppression effect. Flame retardants should not negatively affect the mechanical properties of composite materials. The flame retardancy project meets this challenge and analyses the effectiveness of boron-containing flame retardants, their efficacy and their influence on composite materials' properties.

The research Project IGF-No. 21318 N of Forschungskuratorium Textil e. V. was funded by the Bundesministerium für Wirtschaft und Energie in the framework of the program Industrielle Gemeinschaftsforschung (IGF) based on a decision by Deutscher Bundestag.

In the course of the legally required increase in resource and energy efficiency, natural fibres are already being used for low-stressed components in series production, e.g., for interior trim panels in automotive applications. The available mechanical potential of the natural fibres is often not fully exploited. However, producing components that withstand high mechanical loads requires high- quality semi-finished products. High-quality yarns and technical textiles made of natural fibres can significantly exceed the costs of conventional semi-finished products. A major goal of the project was to produce low-cost, high-quality yarns from bast fibre bundles (hemp and flax) from cheaper staple fibres. The fibres in the yarn must barely be twisted to enable a good fibre alignment in the load direction. Within the project, a composite material was produced from the developed semi-finished products for a narrow-gauge railway leaf spring element with optimised damping properties.

This work was supported by the Federal Ministry of Food and Agriculture (BMEL) on the basis of a resolution of the German Bundestag (funding No. 22026215, 22014817 and 22015417).